AUTOHOME WORLD LEADER IN SOLD

QUANTITIES, FOR ITS IMPRESSIVE

MODEL RANGE AND INTERNATIONAL

DISTRIBUTION NETWORK.

Being number one in sales means leading the market and facing the challenge of competitors and imitators. They do not always provide accurate figures. So the manufacturer has decided to publish the true comparison between AUTOHOME® and a similar but competing product, so you can see the difference.

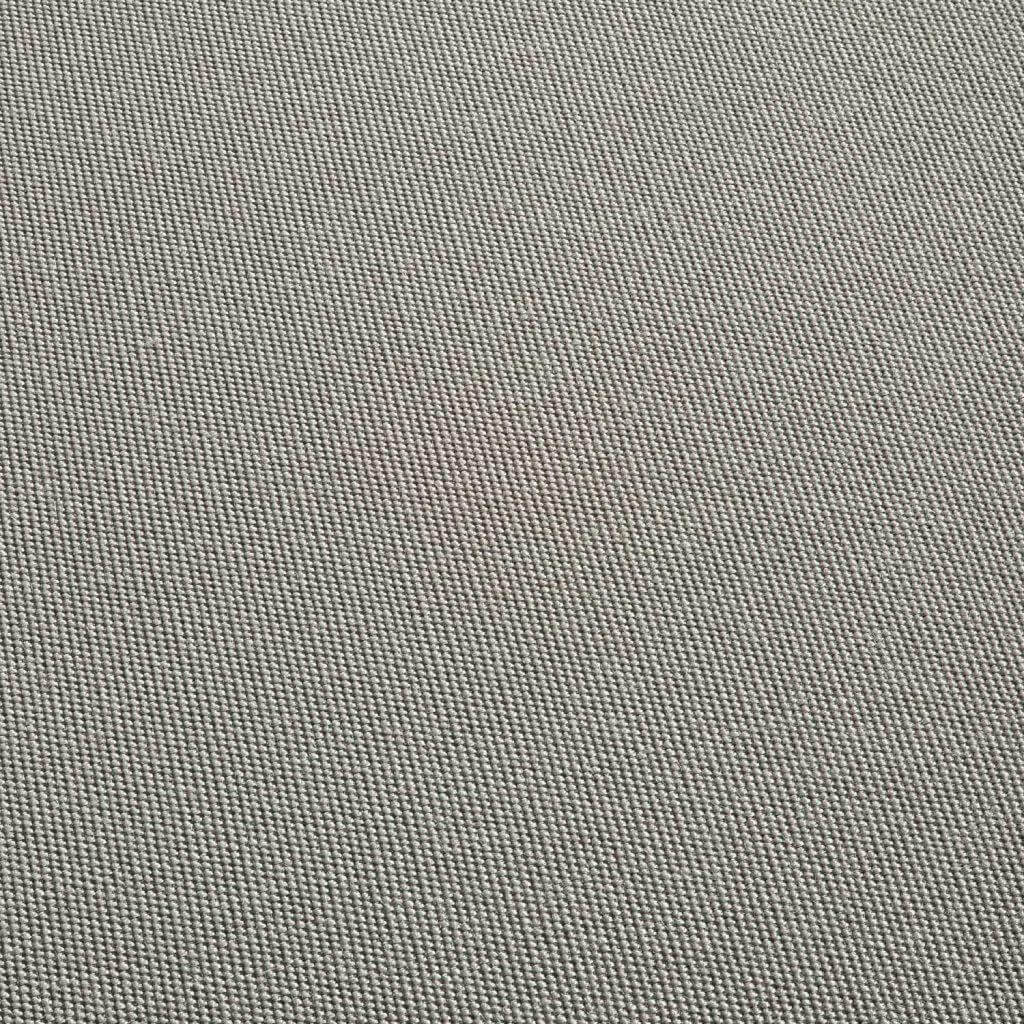

Autohome has excluded all aesthetic considerations which are important but cannot be measured objectively, focusing on practicality and the functioning of the tent, and that means the fabric.

THE FABRIC

ANALYSIS OF A COMPETITOR’S FABRIC AND THE ORIGINAL AUTOHOME TENT FABRIC®

ESSENTIAL FEATURES

According to the Autohome technical team.

A bivouac fabric should not only be waterproof or “hermetically sealed”.

If it were only that, it would be suffocating. It should be breathable, especially because the sleeping area is very small. Every square centimetre of the fabric should help the natural change of air, for genuine wellbeing, which only a highly breathable fabric and the rapid expulsion of water vapour can provide. Technically speaking, a slightly breathable fabric increases condensation, moisture and heat, as any serious manufacturer knows.

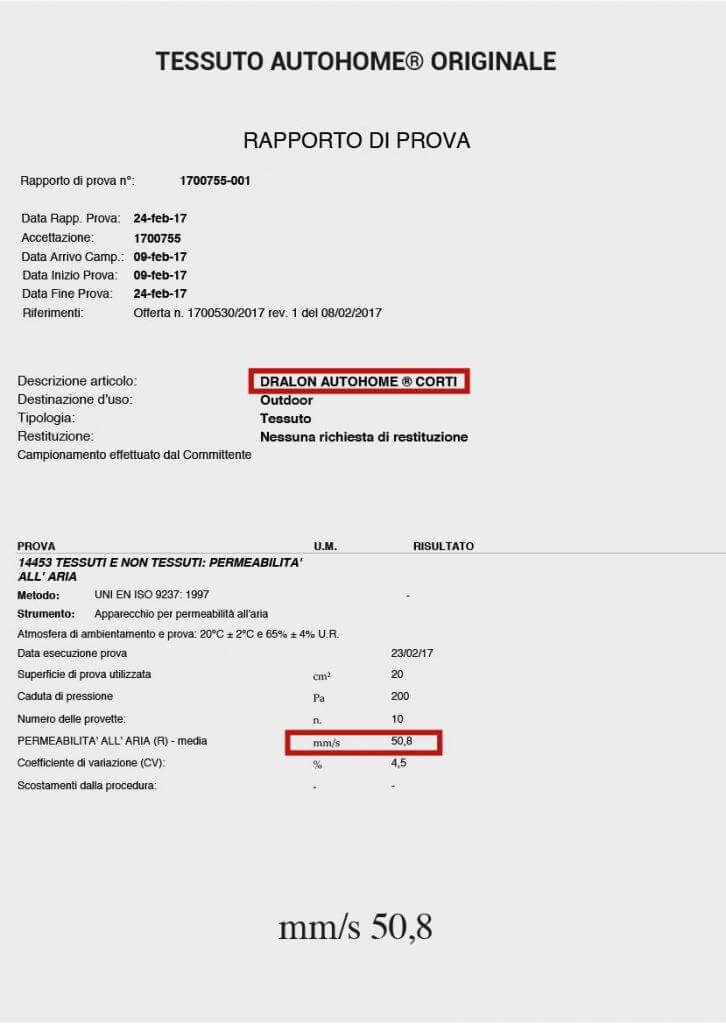

BREATHABILITY

Test to measure the transit speed of the air from the inside to the outside. Method: UNI EN ISO 9237/97

The result is clear and unequivocal.

THE AIR DOES NOT PASS THROUGH THE COMPTITOR’S FABRIC.

This should not be overlooked because non-breathability increases moisture, condensation and heat, making the environment unhealthy.

Alternatives to breathable fabrics, such as moving the air with some mechanism, may help a little, but they do not improve comfort much and do little to contribute to health.

Healthy camping is impossible without breathability.

The lack of breathability is serious and compromises health: in normal conditions, at rest, the human body loses a third of a litre of water overnight, and – without breathability - this moisture is trapped inside the tent, creating droplets on the inner walls.

The second attempt to solve the problem adopted by the competitor is to increase the number of zips and openings, to ventilate the environment. But this means you are sleeping in contact with the outer environment, which may cold, be lit up and it may be raining.

WHEREAS AUTOHOME DRALON®, A HIGHLY BREATHABLE FABRIC, ALLOWS THE TENT TO “BREATHE” NATURALLY.

This is the essential feature of the extraordinary quality of the fabric used by Autohome.

Herat, moisture and condensation can escape from the tent naturally: 24/7. A precious fabric and a must for Autohome®, which has used it since 1980, despite the extra cost.

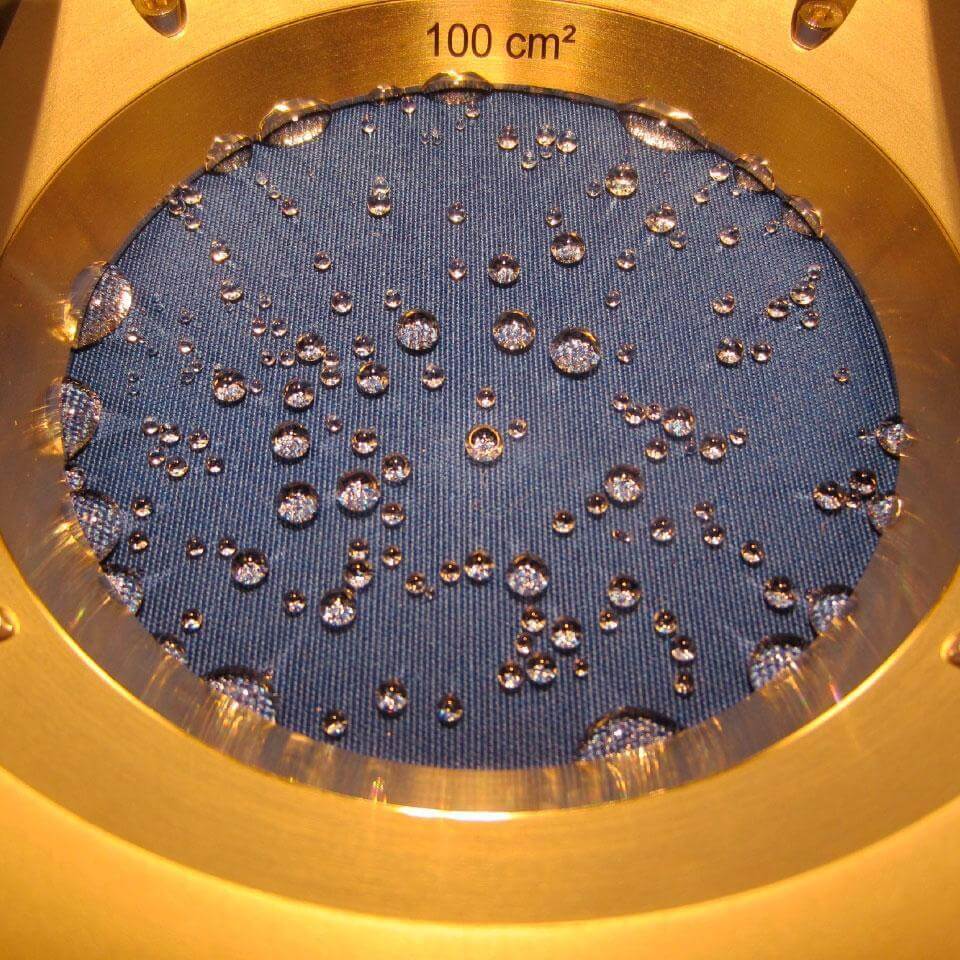

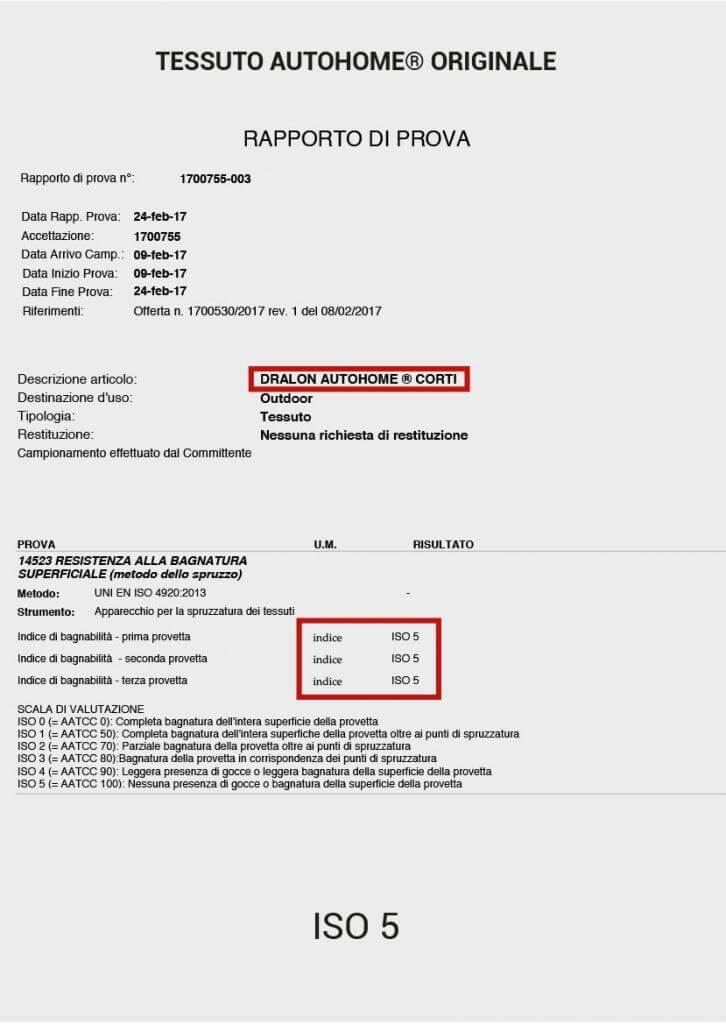

WATERPROOFING

Test that measures wettability when a fabric is used vertically, expressed from 0 to 5. Method: UNI EN ISO 4920/13

The competitor’s fabric becomes wetter and its stitching is less secure. A plasticized, dry fabric is more rigid and difficult to stitch: the holes made by the needle tend to stretch due to the tension and traction of the tent, so rainwater can get in. The competitor’s tent is shown with dangerous stitching where the fabric is attached to the shell.

Trying to tape over the holes does not help: and proper maintenance with resin or silicone needs to be repeated often.

AUTOHOME DRALON® FABRIC IS HIGHLY WATER RESISTANT. THE FIBER IS SOFT AND COMPATIBLE WITH STITCHING, AVOIDING PROBLEMS. THE STITCH HOLES REMAIN MINUTE AND DO NOT LET IN RAINWATER. THE STITCH THREAD NATURALLY EXPANDS IN THE RAIN COVERING THE HOLES ENTIRELY.

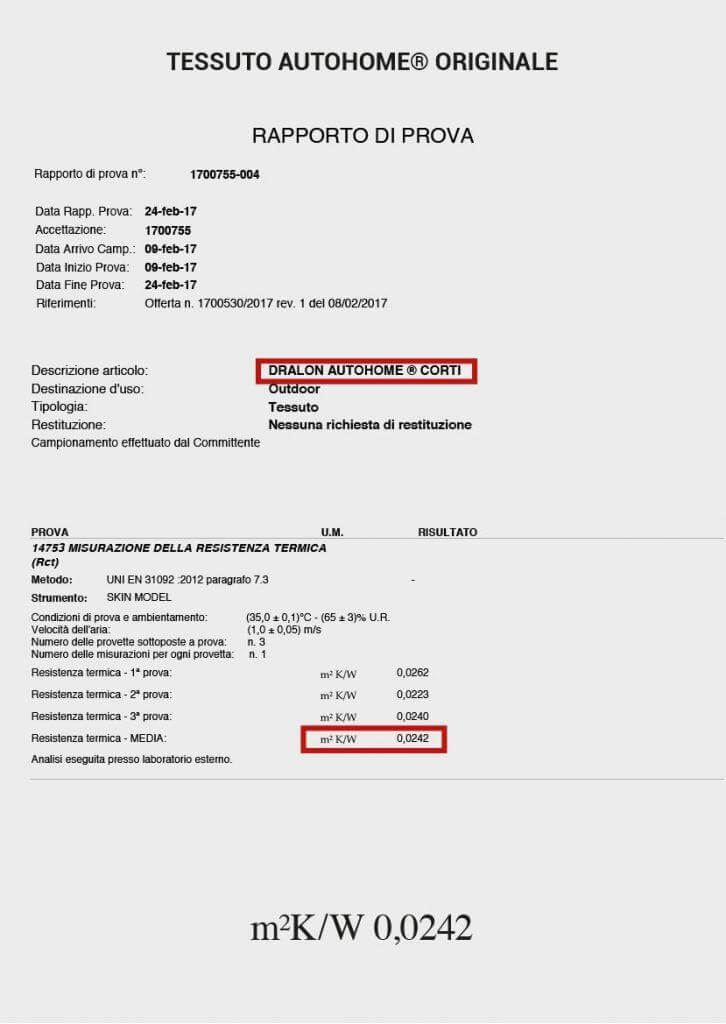

HEATPROOFING

Test that measures the heat resistance of the fabric in relation to heat loss from the tent. Method: UNI EN 31092/12

The test shows that the competitor’s fabric heats up more.

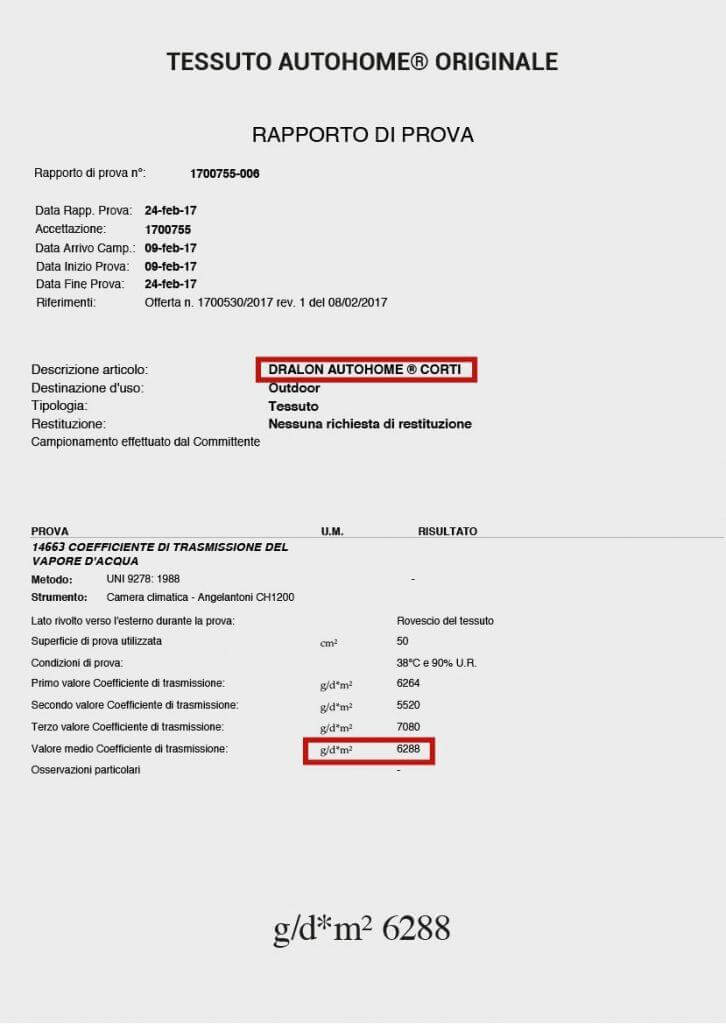

WATER VAPOUR TRANSMISSION COEFFICIENT

Test that measures how much water vapor passes through one square meter of fabric in 24 hours. Method: UNI 9278/88

The result is clear and unambiguous! There is no comparison: 536 g/d*m2 against 6288 g/d*m2.

An advantage for Autohome of 5752 g/d*m2.

THE TESTS SHOW THAT THE COMPETITOR’S FABRIC HEATS UP AND RETAINS WATER VAPOR.

That’s why the competitor’s tent is full of openings, diminishing privacy.

Fitting an anti-condensation stack to the roof of the tent is a tacit admission (never mind the aesthetics) that the fabric is not breathable.

The stack is fitted to a hole in the roof, another way rainwater can get in.

THE TESTS SHOW THAT, ON THE CONTRARY, AUTOHOME® DRALON ALLOWS THE HEAT TO ESCAPE AND ENABLES THE CIRCULATION OF AIR, BOTH QUALITY REQUIREMENTS.

AND YOU DON’T NEED A STACK OR PLENTY OF OPENINGS, RUINING COMFORT AND PRIVACY.